Strapping band is one of the most widely used materials for securing cargo and goods. However, it is sometimes difficult to judge exactly what kind of strapping is appropriate. Here you’ll learn about three types of strapping band- polypropylene, polyester and metal – and which strapping band is recommended for your business.

Polypropylene Strapping band

Polypropylene strapping band is often also called plastic strapping or PP strapping. Whatever it may be called, polypropylene band began gaining popularity in 1957 and is one of the most widely used packaging bands today. This is so for multiple reasons. Here we will look at the characteristics of plastic strapping, its uses and its applications in industry.

Features of the plastic band

Clamping the plastic strapping

The PP band can be used in three different ways – by vibration brazing, by hot brazing and by metal clips / clamps / for the strapping. Let us consider the three options separately.

Vibration brazing

The vibration brazing or friction brazing method secures the PP strip by rubbing both ends of the strip very quickly. Thus, neither thermal heating nor metal clips are used for fastening.

Hot brazing

Like its name, this method is accomplished by using high temperature. The two ends of the strapping are pressed firmly and soldered together by high temperature, creating an extremely strong bond. As with vibration brazing, no metal clips are required for attachment. However, semi-automatic, automatic or portable strapping machines are required according to production needs. Most often this type of strapping is suitable for high-capacity production and strapping use.

Metal seals /clamps/

Applications of polypropylene strapping

As we said at the beginning, plastic strapping is used in many industries to package light to medium loads. It is a preferred option because of its durability, flexibility, and low cost compared to other types of gaffer tape. These are some of the industries where polypropylene strapping is a common option for securing loads:

Paper industry

Woodworking

Food industry

Plastic industry

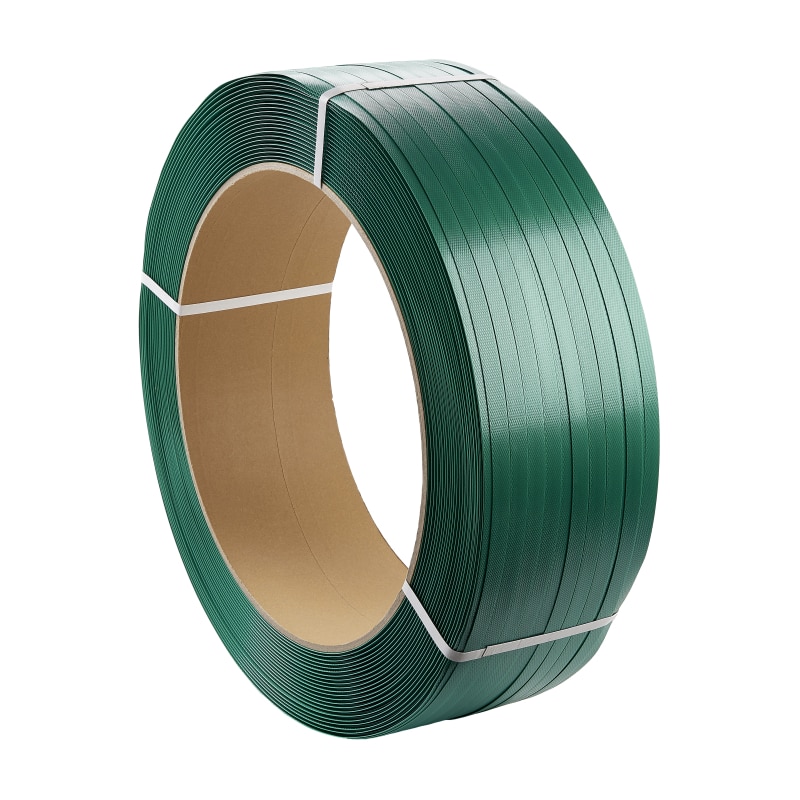

PET Strapping Band

Polyester strapping is also called PET strapping for short. Although it is visually very similar to polypropylene band, it has much higher strength characteristics. It is because of these characteristics that polyester strapping band is one of the greatest packaging innovations. Thanks to them, it largely displaces the metal strapping. Here we will look at the characteristics of polyester webbing, its uses and its applications in industry.

Characteristics of polyester band

Clamping the polyester strapping band

Like PP band, PET band can be used in three different ways – vibration brazing, hot brazing and metal buckles. Here we will look at all three gripping options separately.

Vibration brazing

Vibratory brazing is characterized by extremely fast rubbing of both ends of the strap. As a result, the two ends are soldered together. This clamping method does not use thermal heating or metal buckles. However, it does require the use of a specialised cordless deburring machine to carry out the rubbing.

Hot brazing

Hot soldering reattaches the two ends of the strapping without the use of metal buckles. In this method, however, the strapping is pressed hard and the two ends are glued together by the use of very high heat. This method requires the presence of a semi-automatic, automatic or portable cordless thermal heating machine. This is why this method is suitable for high-capacity or automated production lines. Of course, this method is also reasonable for small industries that have the funds available to invest in the more expensive hot brazing machines.

Metal buckles

Applications of polyester strapping

As mentioned at the beginning, PET tape is used in many industries to secure heavy loads as a replacement for metal strapping. Due to its elasticity, strength, safety and low cost, it has successfully established itself as the preferred packaging material for heavy goods and cargo. These are just a few of the industries where polyester webbing is used extensively:

Woodworking

Building materials

Metal products

Metal strapping

Metal band is the strongest strapping that can be used. This band breaks under the most load. However, it is not elastic and is considerably more dangerous to use than polyester and polypropylene. Precisely because of its inflexibility and high cost, metal tape has been almost entirely replaced by polyester tape. However, the metal still finds application in some industries. Here we will look at the characteristics of metal tape, its uses and its application in industry.

Characteristics of the metal strip

Let’s first look at the pros of metal band. Firstly, it has extremely high breaking strength, making it suitable for palletising very heavy loads. Secondly, metal strapping, unlike plastic strapping, does not stretch, which means that if the goods are left tightened for a long time, the strap does not lose its tightness. Third, the metal band is resistant to both high temperature and sunlight, and moisture.

Of course, metal tape also has disadvantages, which is why it has been almost entirely replaced by polyester and textile band. Firstly, precisely because the metal band does not stretch, it can break under transport or other shocks. Second, it is much more expensive than any other strapping band, which greatly increases packaging costs. Thirdly, the metal strapping tape is much heavier than other types of band. Fourth, although on many metal strips the edges are rounded, it still remains the most dangerous option for strapping.

Clamping the metal strapping

Unlike other strapping bands, metal strapping does not have many gripping options. Moreover, the clamping of the metal tape is considerably more labor-intensive than that of the polypropylene or polyester tape. There are actually two types of metal tape application tools – manual and pneumatic. Let’s look at the two options.

Hand tools

Clamping the metal strapping band with hand tools requires three different tools – tensioner, pliers, and scissors. In addition, metal staples are also required. The process of combering is as follows. First, the strapping tape is pushed through the bracket. Second, the band is tightened by the turnbuckle. Third, the clamp is tightened by the pliers. Fourth, the remaining band is cut. Of course, the band can also be broken by moving the tensioner up and down instead of cutting it with scissors. Of course, there are also combination handheld machines i metal strapping, which combine all three functions in one.

The metal staples are divided into four types – open, closed, open flange, and pre-bent. The first type of brackets are not pre-bent, the second and third types are pre-bent, and the fourth is not. Open clamps are the easiest to use. The closed clamps are pre-bent and the strap is inserted into the clamp. The pre-bent clamps are pre-bent before the clamping point of both ends. Open flange clamps can be placed before or after the connection and are used for the heaviest loads.

Pneumatic tools

Metal strapping using pneumatic machines has the same steps as hand strapping. The difference is that pneumatic tools run on air and are less mobile than hand tools.

Applications of the metal strapping

As previously mentioned, metallic webbing has been heavily displaced by polyester webbing in many industries. However, metal strapping remains the preferred strapping option when extremely heavy loads are involved.Some of the applications of metal strapping are in:

Industrial machinery

Building materials

Metal products